Craqueamento catalítico

Maximizing naphtha production for gasoline blending or ethylene/propylene production for petrochemical feedstock requires reliable and efficient catalytic cracking units. To improve profitability, high heat recovery, even in severe fouling environments, is essential. Alfa Laval Compabloc and spiral heat exchangers are therefore excellent tools to maximize plant uptime and profitability.

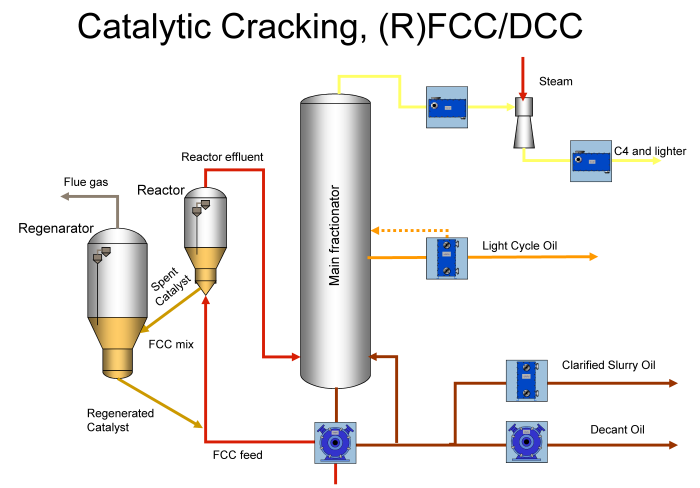

Optimizing fluid catalytic cracking processes

Converting hydrocarbon fractions into more valuable refinery products can be done in fluid catalytic cracking (FCC) processes. Alfa Laval has the expertise, technologies and services to help refineries balance the need for reducing energy consumption and environmental impact with increasing uptime and yields.

Energy efficiency in fluid catalytic cracking

Energy content in the vapour leaving the main fractionator can be high. However, if energy would be recovered in traditional shell-and-tube heat exchangers, several large exchangers in series would be needed due to the low vapour temperature. When you factor in the costs for high-grade, corrosion-resistant material and installation on construction, it is no longer feasible to recover energy due to the high costs. Instead energy is typically wasted by means of cooling and/or condensing the vapour in air coolers.

Alfa Laval Compabloc heat exchangers offer a smart alternative. Designed to recover energy even from low-grade sources, Compabloc units minimize the heat transfer area as well as the number of heat exchangers and plot space required to achieve high energy efficiency. They recover most of the energy in the vapour, often redirecting it into boiler feed water preheating system or district heating system.

The main fractionator bottoms slurry (decant oil) is also a huge source of energy. Most refineries use this slurry to preheat the feed, generate steam and sometimes as a heat bulk for other process units.

Normally, several large traditional shell-and-tube heat exchangers in series are required to recover this energy, and frequent cleaning is needed due to the high fouling tendencies of the slurry. In many cases, stand-by equipment is recommended to maximize energy efficiency while exchangers are being cleaned.

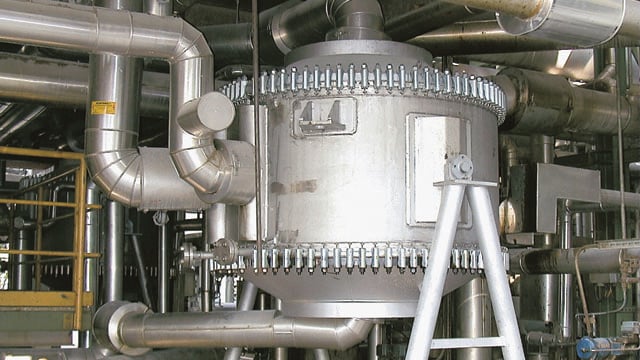

High efficiency Alfa Laval spiral heat exchangers maximize energy recovery from the slurry while minimizing fouling tendency and maintenance requirements.

Mitigating fouling in fluid catalytic cracking

The main fractionator bottoms slurry (decant oil) often has high-fouling tendencies because it contains a high load of catalyst particles as well as coke particles and ash from the fractionator column. Shell-and-tube heat exchangers experience high fouling tendencies due to their inherent design with dead zones in the turning chambers and the risk of maldistribution at the tube sheets. This makes it difficult, if not impossible, to control flow velocities inside the tube channels.

Alfa Laval spiral heat exchangers are tailor-made to handle process fluids with a high content of solid particles. Their single channel design helps easily control flow velocities and avoid maldistribution. In addition, there are no dead zones where material can build up. This means that no cleaning is required and that it is possible to achieve maximum heat transfer efficiency over time – even when catalyst is carried over into the main fractionator column.

Increasing capacity

Creeping the capacity of the FCC process can be very expensive if there are bottlenecks in equipment involving the capacity of the fired heater preheating the feed, the air blower in the catalyst regeneration or LPG compressor systems.

Alfa Laval spiral heat exchangers maximize preheating the feed prior to the fired heater. This can offload the fired heater, making it possible either to process more feed or to further increase the reaction temperature . With a higher reaction temperature, less catalyst is needed. This reduces the amount of air required for catalyst regeneration and offloads the air blower thereby increasing the plant capacity.

Moreover, Alfa Laval Compabloc heat exchangers are typically installed as condensers for the fractionator overhead vapour in order to maximize condensing and cooling, thereby offloading the compressors.

Corrosion resistance

The overhead vapour from the main fractionator can be very corrosive because the vapour contains salts that can sublime and form deposits on the heat transfer walls of the heat exchanger.

This means that carbon steel can suffer from under-deposit corrosion and require frequent repair or bundle replacement. To avoid corrosion-related issues, Alfa Laval Compabloc heat exchangers can be supplied in high-grade materials that are corrosion resistant for this type of service. This helps eliminate the need for repair and replacement.

CAPEX savings in fluid catalytic cracking

Shell-and-tube heat exchangers become very expensive, especially when recovering energy with several large, bulky exchangers that require backup equipment when cleaned, or when using high-grade material to ensure sufficient corrosion resistance. With the low-fouling tendency of Alfa Laval spiral heat exchangers, no spare units are needed.

In addition, with high-efficiency Alfa Laval heat exchangers, up to three times less heat transfer area is required. This significantly reduces capital expenditures, especially when agressive media calls for the use of high-grade material.

Finally, because Alfa Laval heat exchangers can handle crossing temperature programs in a single exchanger, the number of exchangers required for a heat recovery service is minimized. In addition, the total installed cost can also be reduced. This is true even when installation on construction is required for vapour condensing services.

Proven technology for catalytic cracking

Alfa Laval has more than 100 heat exchangers operating in FCC units around the world. Out of these, more than 50 Alfa Laval spiral heat exchangers are installed either as slurry/feed interchangers or as slurry coolers. What’s more, approximately 40 Alfa Laval Compabloc heat exchangers are installed as overhead vapour condensers for the main fractionator.