What is membrane filtration ?

With experience extending as far back as 1965, Alfa Laval's specialists can answer the question in detail. Membrane filtration process is a physical separation method characterized by the ability to separate molecules of different sizes and characteristics. Its driving force is the difference in pressure between the two sides of a special membrane. Membrane technology enables you to bring down overall production costs, and boost product quality at the same time.

What is membrane filtration and how does it work?

Membrane filter as a physical barrier

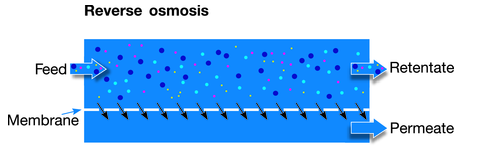

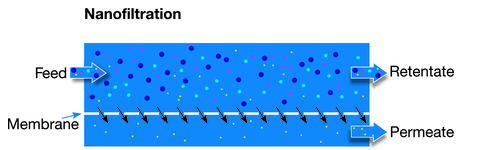

So, what is membrane filtration? In its most basic terms membrane filtration involves passing a single feed stream through a membrane system that separates it into two individual streams, known as the permeate and the retentate. The membrane that separates them is a physical barrier with highly specialized characteristics – a barrier that only certain selected components in the feed stream can pass through.

Passing through

The pores of such membrane material are so small that they are measured in Angstrom (10-10 m), and pressure is required to force the liquid through them. In fact, the pores in the membranes used for nanofiltration and reverse osmosis are so small that they cannot be seen even with a scanning electron microscope.

Types of membrane filtration

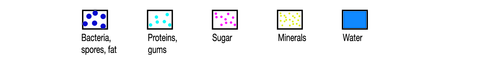

There are four commonly accepted types of membrane filtration. These are defined on the basis of the size of material they are required to separate from the feed liquid. The four types of membrane filtration are known as reverse osmosis, nanofiltration, ultrafiltration and microfiltration, in order of increasing pore size. Our flat sheet membranes and spiral wound membranes covers these types of membrane filtration.

What is reverse osmosis (RO)

Reverse osmosis uses the tightest possible membrane in liquid separation. In principle, water is the only material that can permeate the membrane. All other materials (bacteria, spores, fats, proteins, gums, salts, sugars, minerals etc.) will be unable to pass through.

Read more about our RO flat sheet membranes and RO spiral wound membranes

What is nanofiltration (NF)

Nanofiltration allows small ions (eg minerals) to pass through while excluding larger ions and most organic components (eg, bacteria, spores, fats, proteins, gums and sugars).

Nanofiltration (NF) VS Reverse osmosis (RO)

Nanofiltration is not as fine a separation process as reverse osmosis, and uses membranes that are slightly more open.

Read about our NF flat sheet membranes and NF spiral wound membranes

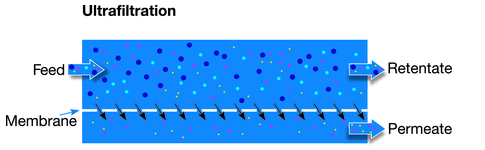

What is ultrafiltration (UF)

Ultrafiltration involves using membranes in which the pores are larger and the pressure is relatively low. Salts, sugars, organic acids and smaller peptides are allowed to pass, while proteins, fats and polysaccharides are not.

Read about our UF flat sheet membranes and UF spiral wound membranes

What is microfiltration (MF)

In microfiltration, suspended solids, bacteria and fat globules are normally the only substances not allowed to pass through.

Read about our MF flat sheet membranes and MF spiral wound membranes

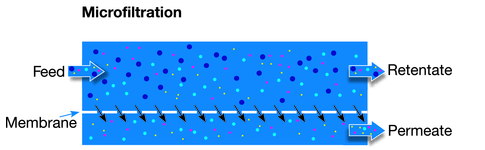

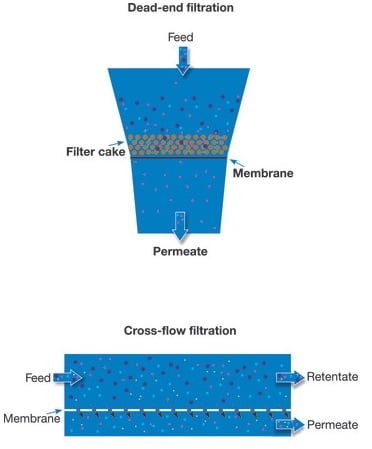

Cross-flow filtration VS Dead-end filtration

Membrane filtration can be either dead-end filtration or cross-flow filtration.

Cross-flow filtration provides significant built-in advantages over dead-end filtration. Because the liquids being processed flow continuously across the membrane, there is no filter cake that can lead to fouling and uneven flow.

This makes it possible to operate a continuous, automated filtration process that results in a consistent, controllable product quality. No filter aids are needed, and the membranes have an extended lifetime.

Almost all industrial membrane filtration is carried out as cross-flow filtration, where the liquid being filtered flows parallel to the membrane at high velocity and under pressure.

Advantages of membrane filtration

There are many significant advantages of membrane filtration when used in industrial-scale applications where reliability, consistency and operating costs are crucial considerations.

Lower overall production costs

One of the advantages of membrane filtration is that membrane filtration systems often are less expensive than many other alternative technologies. The installation costs are lower, as are the energy costs.

Membrane filtration includes fewer processing steps and makes it possible to achieve both a greater degree of purity and higher overall yields.

In addition, because membrane filtration does not result in a filter cake, there are no costs associated with the removal and disposal of this residue.

High flexibility

Membrane filtration can be used for feed products with a range of different viscosities, including high-viscosity products that can otherwise be difficult to process. A wide range of different membrane filtration products also ensures that the best possible solution is available for each particular application. This also eliminates unnecessary energy costs.

High end product quality

Membrane filtration is a clean technology. The separation process is carried out solely on the basis of molecular size, making the use of additives unnecessary. This results in an end product with top quality, and makes it easier to comply with the many stringent requirements from both consumers and public authorities.

Case stories

Many reference installations can be found across a wide range of industries. They include:

History of Alfa Laval membrane technology

Alfa Laval’s experience within membrane filtration and membrane filtration systems dates back almost as far as technology itself. Since the mid-sixties, soon after membrane filtration was introduced on a commercial scale, we have been helping our customers with the membrane technology.

Our diverse types of membranes and membrane products, from membrane sheets(flat sheet membranes or spiral wound membranes) to auxiliary membrane equipment, from test units or pilot plants to production units, complement our wide range of separation technologies such as the use of decanter centrifuges and disc stack separators. This allows us to provide you with the most efficient solution.

Complete familiarity

Buying membrane filtration solutions from Alfa Laval means you are tapping into the know-how and experience that comes from complete familiarity with every step of the process. With experience extending as far back as 1965, Alfa Laval specialists can develop and fine-tune a solution that meets your exact needs, combining your expertise in your particular field of processing with our unparalleled membrane filtration know-how. The expert Alfa Laval staff are probably unique in their ability to address your needs at whatever stage of the process chain.

Complete consistency

We are one of the few companies in this field with the capacity, expertise and experience to develop, manufacture and install membrane elements, modules, and complete membrane filtration systems, as well as to serve our customers. When you include membrane filtration technology in your process solutions, you can rely on it completely.

Completely tested

We are also one of the very few companies in the world that can scale its membrane filtration know-how seamlessly from R&D, testing and trials up to full-scale manufacture, and process implementation that you and your company can rely on completely.

Moreover, we have our own extensive test facilities in Nakskov, Denmark. Our facilities allow you to develop solutions for your specific process alongside with our expert staff. We also have a wide range of pilot laboratory equipment available if it is more convenient for you to do the work on your own premises.

An extensive range of membrane filtration solutions

The range of membranes from Alfa Laval covers all filtration processes – reverse osmosis, nanofiltration, ultrafiltration and microfiltration. We have a comprehensive range of spiral elements and flat sheet membranes. We also provide pilot laboratory equipment. Our membrane filtration equipment is designed on a modular basis that gives a high degree of flexibility, as membranes are built into modules, modules are built into loops and loops are built into systems. The design of a system can thus be customized to meet any process needs and it is easy to expand if production requirements increase. This means that your investment can follow any required increase in production capacity, as and when you need it – and at relatively low additional cost.

Membrane types

- Flat sheet membranes (RO/NF/UF/MF)

- Spiral membranes (RO/NF/UF/MF)