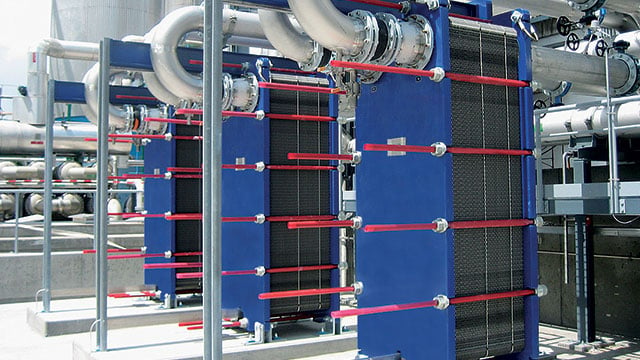

Optimize your gasketed plate heat exchanger for the future

A gasketed plate heat exchanger is a stationary piece of equipment without any moving parts, but they still require routine maintenance to optimize performance - just like any other critical process equipment in your production facility. However, heat exchanger maintenance intervals can vary widely, depending on various factors, such as: media, temperature and pressure. Which is why it is important to assess the performance of your gasketed plate heat exchanger.

Alfa Laval Visual Condition Assessment will give you a quick overview of the state of your gasketed plate heat exchangers. You will gain insights about the actual condition of your equipment its detailed mechanical condition, need of repair and remaining gasket lifetime prediction.

We will also provide you with a report, containing:

- Unit data including any changes and adaptations

- Pictures and description of problem areas

- Thermal image of your unit with an interpretation

- Our summarized findings and recommendations

With a Visual Condition Assessment we work closely with you to identify and resolve any issues that require attention. Using a thermal imaging camera enables us to evaluate the thermal performance and make recommendations to maintain your heat exchangers in top operating condition based on our findings and analysis. With our recommendations you can plan the maintenance at your convenience and Alfa Laval can give safety advice on the spot.

Want to know more? Download the leaflet

What do you get from a VCA done by us?

Detailed report with thermal image and recommendations of each GPHE

After our visit we will provide you with a detailed report for each unit we have assessed. The report will contain thermal image as well as other relevant images, heat exchanger data and our observations and recommendations for optimal performance.

Fast execution - no need to open the units

VCA is best done with the unit in operation. This enables us to make a thermal image. Each unit is typically assessed in less than 5 minutes depending on size and accessibility.

Notifications of potential safety and performance issues

Safety is on the top of our agenda in Alfa Laval. All our service technicians are trained to work in a safe manner, and they will let you know if they see any safety issues around your heat exchangers. Heat exchanger performance will be assessed based on the thermal image as well as on information received from you. You can discuss performance with our service technician directly in front of your plate heat exchanger.

Get short- and long-term maintenance recommendations

Based on our findings and dialog with you, we can provide you short- and long-term maintenance recommendations. This will enable you to plan maintenance and prioritize activities.

Plan maintenance activities based on our findings

Most of our customers prefer planned maintenance over break-down repairs which are always inconvenient. Our findings and heat exchanger expertise will enable us to help you in prioritizing maintenance activities and choosing what to do now and what can be postponed.

Making efficiency last for decades

A poorly functioning heat exchanger may affect safety, product quality and energy costs. Failure may lead to costly downtime and major losses in production. By regular and proactive maintenance of your gasketed plate heat exchanger performance is preserved and operations kept trouble-free and predictable.

We have the expertise to help you whether you experience a problem today, wish to prevent future issues or want to solve the problem yourself with our online troubleshooter.

Otimização de eficiência energética

Todos os anos, a quantidade de trocadores de calor para os quais prestamos serviços visando otimizar a eficiência energética reduz as necessidades de capacidade dos nossos clientes em 50 GW, quantidade de energia que pode ser gerada por 10 mil turbinas eólicas no mesmo período!

Nas emissões de carbono, 50 GW traduzem-se numa redução de 25 milhões de toneladas na nossa pegada global, o equivalente ao carbono emitido pela cidade de Londres todos os anos.

Imagine o que poderíamos alcançar se as indústrias de todo o mundo fizessem a manutenção regular dos seus trocadores de calor a placas para otimizar a eficiência da transferência de calor?